Laser Station ЛКТТД

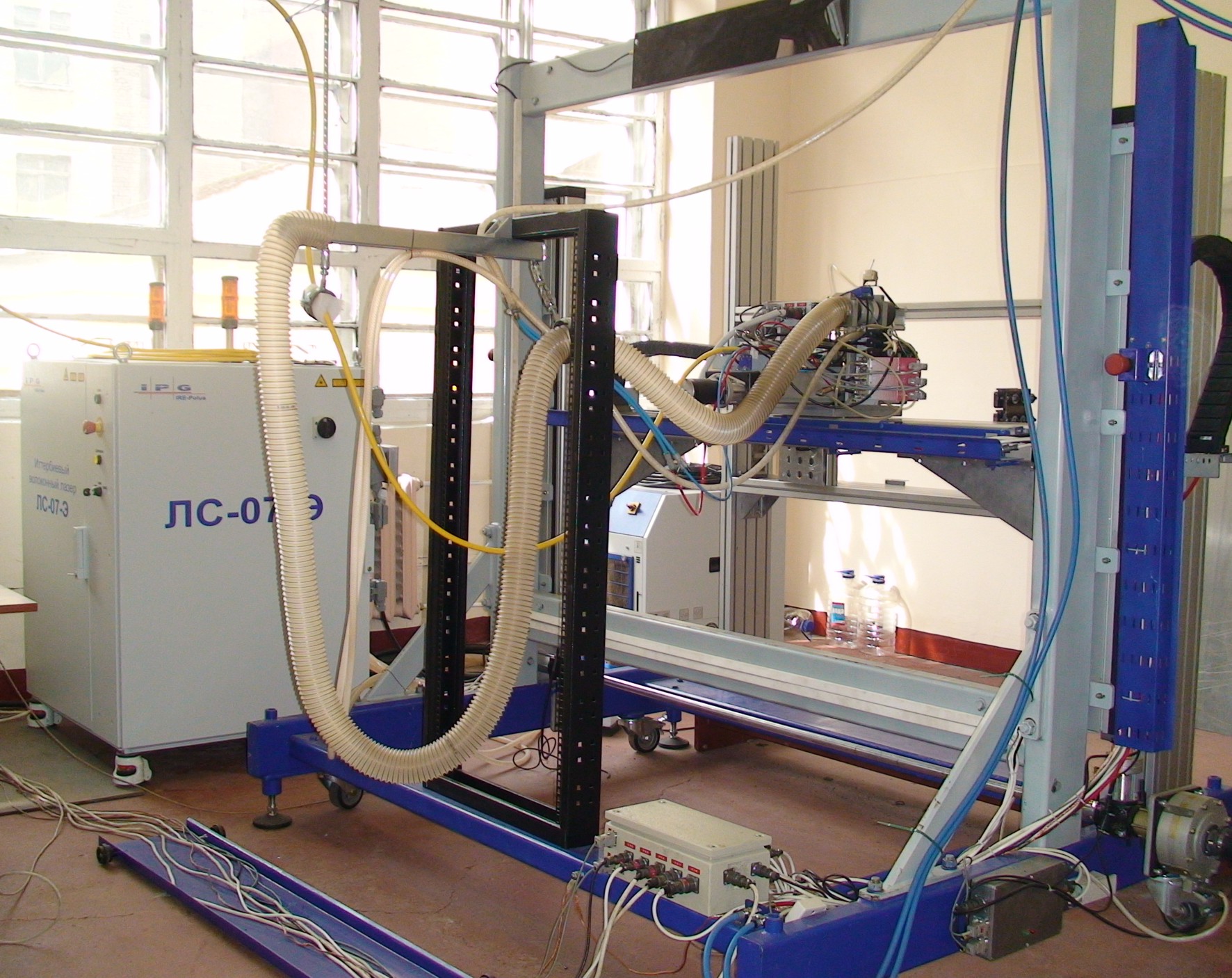

Laser station

The station comprises the following components:

- fiber laser of 1000–2500 W depending on the material of plate and the fusion depth

- mobile welding station

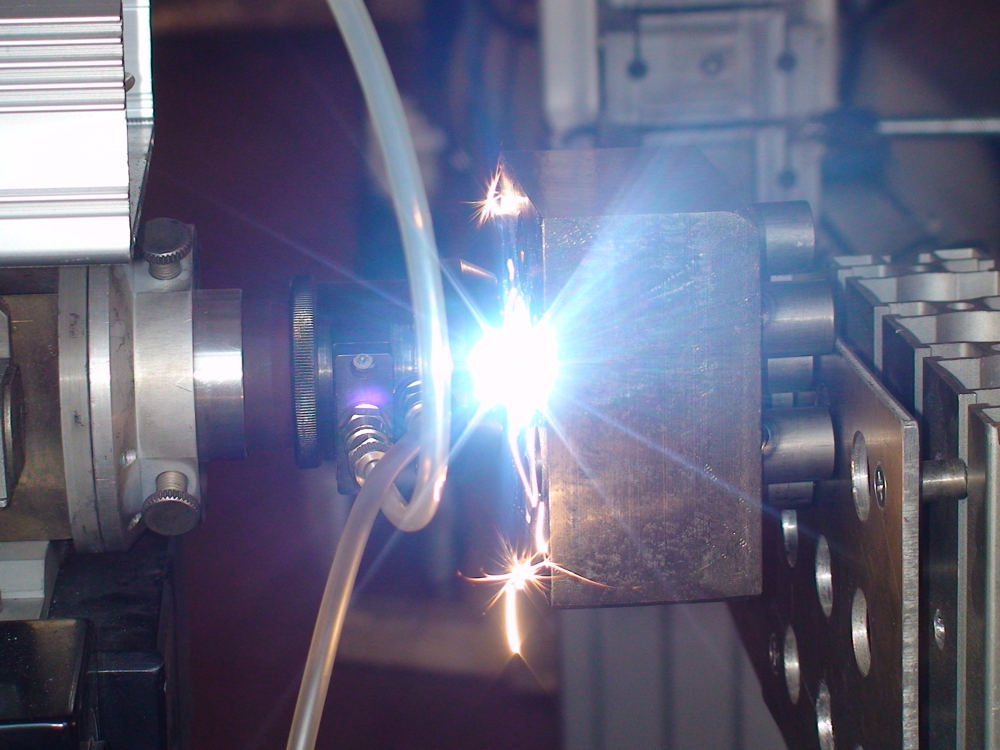

- welding head VF001 with nozzle system ensuring the welding process and protection of metal, including titanium alloys

- digital videosensor ensuring referencing to object and adjustment to tube centre

- control system.

The station control system is built on the basis of network computer numerical control (CNC) of PAC©InSoft architecture using separate processor modules for every piece of equipment (servo drive, laser head, gas regulator, etc.) united in one network by CAN interface. This solution ensures minimization of cabling and high reliability of operation.

Technical characteristics:

| Station type/parameter |

|

Note |

|---|---|---|

| Optical path length | Up to 100 m | From laser to mobile station |

| Radiator power | 1000.3000 W | |

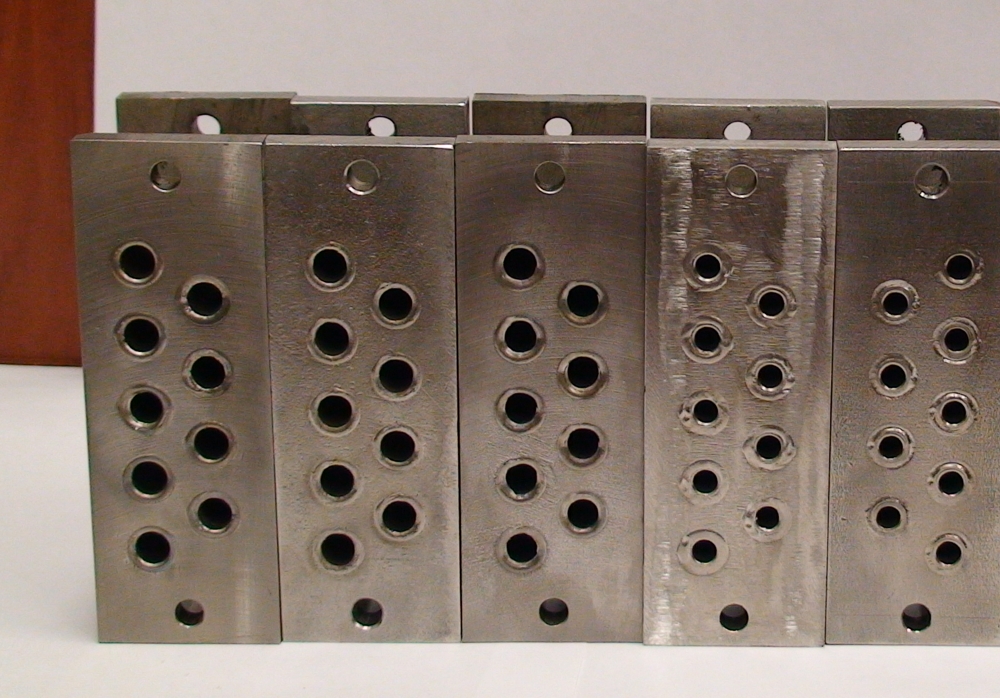

| Tube plate size | 800.1200 mm | Size can be increased to customer’s request |

| Tube plate surface monitoring | Inductive sensor | |

| Welding head type | VF001M | |

|

Targeting |

Digital, accuracy 80 µm minimum |

|

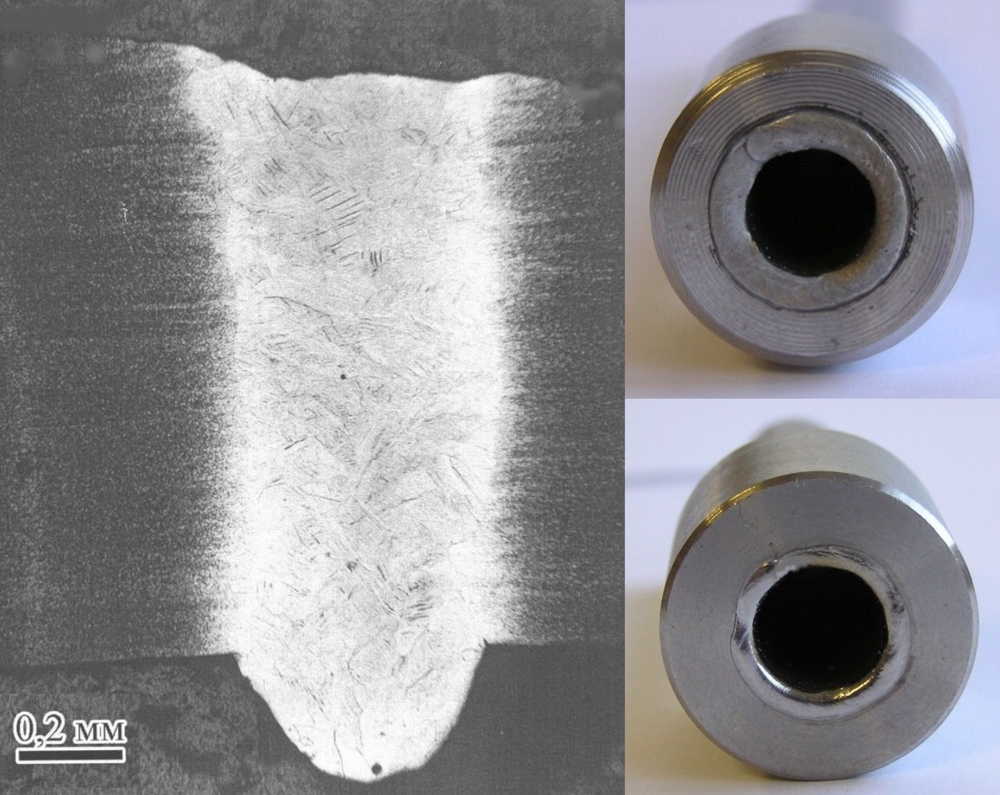

| Special modes |

Preliminary cleaning of seam in pulse mode Finishing pass |

|

| Geometric data input | DXF file | |

| Programming of cycles | Subsystem LW Station | |

|

|

Welding process 2 s max., full operation time 6 s max | |

| Materials |

Stainless steels, titanium alloys, stainless |

|

Delivery options:

-

Laser station

ЛКТТД-01 under agreed Technical Assignment (TA). -

Laser station

ЛКТТД-01 under agreed TA with certification of welded joints.

It is possible to organize preliminary testing on the working station at the Designer.