Laser Cleaning

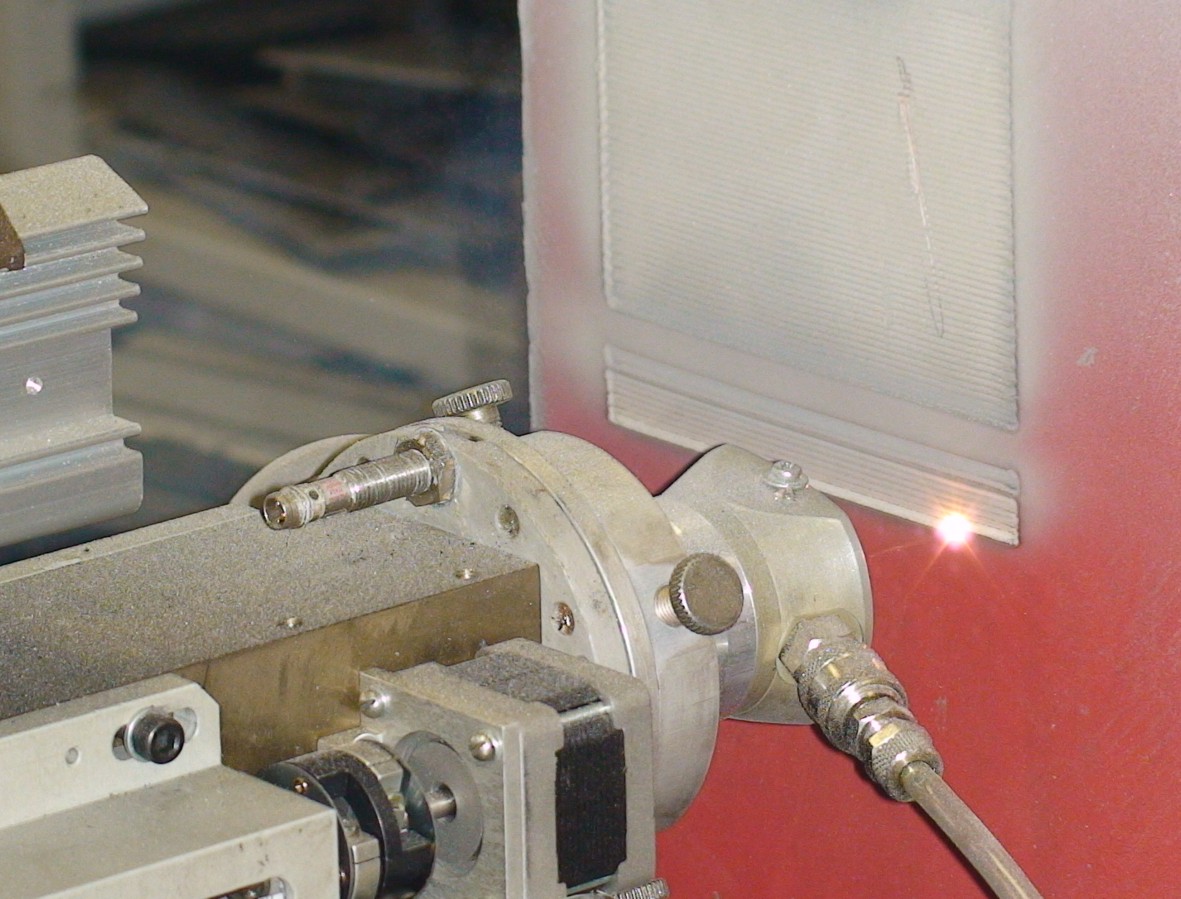

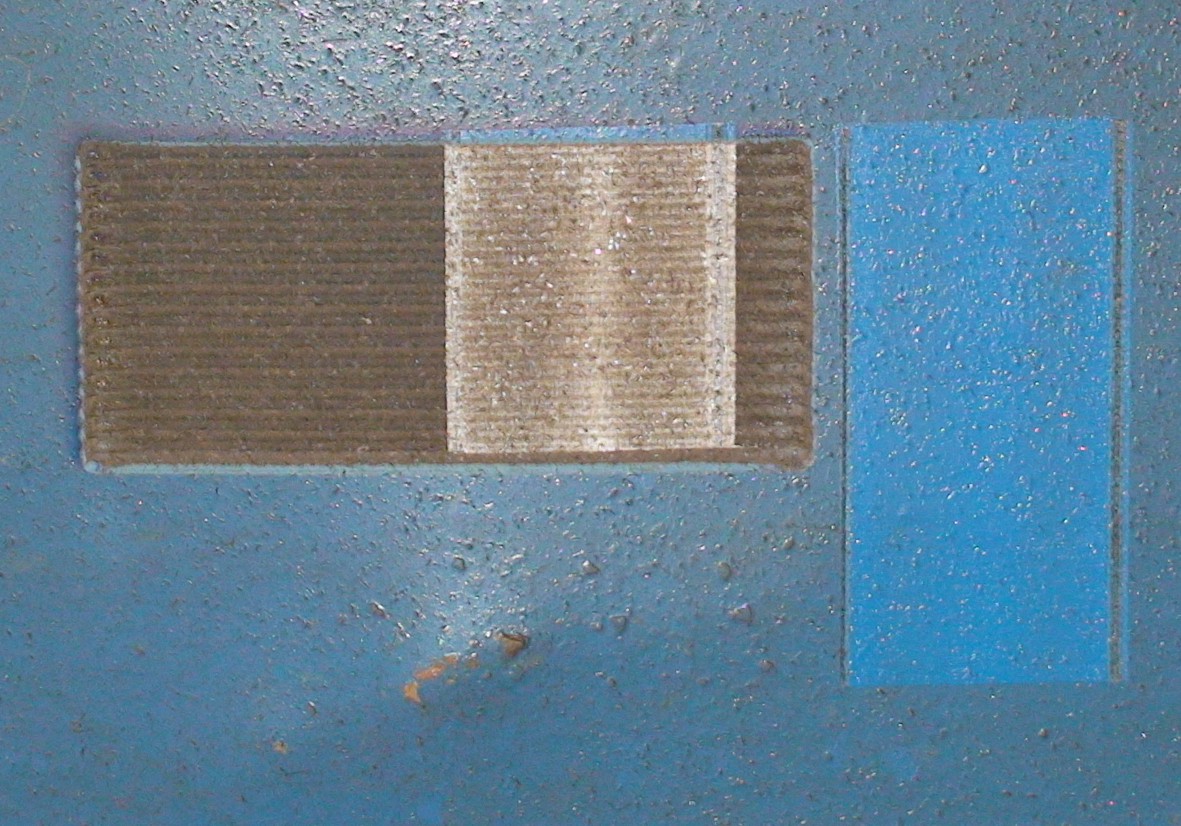

Efficiency of laser cleaning with use of

It is important to note one more positive effect: after such cleaning process the surface is well activated, the metal surface is

This technology can be used in the following industries, both as a stationary equipment and as a mobile cleaning system:

- railway industry, for cleaning of carriages and moving parts and for railway structures, such as bridges and other structures

-

machine-building — for cleaning of any metal items prior to painting and welding -

turbine construction — for cleaning surface of various blades to remove operational

hard-to-remove carbon deposits - aircraft engineering and operation — cleaning of aircrafts during scheduled repaint.

Main advantages of laser cleaning technology:

- absence of abrasives and, as a result, no abrasive wear of treated structures

- no heating

- high efficiency of process

- possibility of automation

- environmental cleanness

- possibility of paint application without additional preparation of surface

- minimum noise

- minimum power consumption.