Laser Perforation

Laser perforation is a

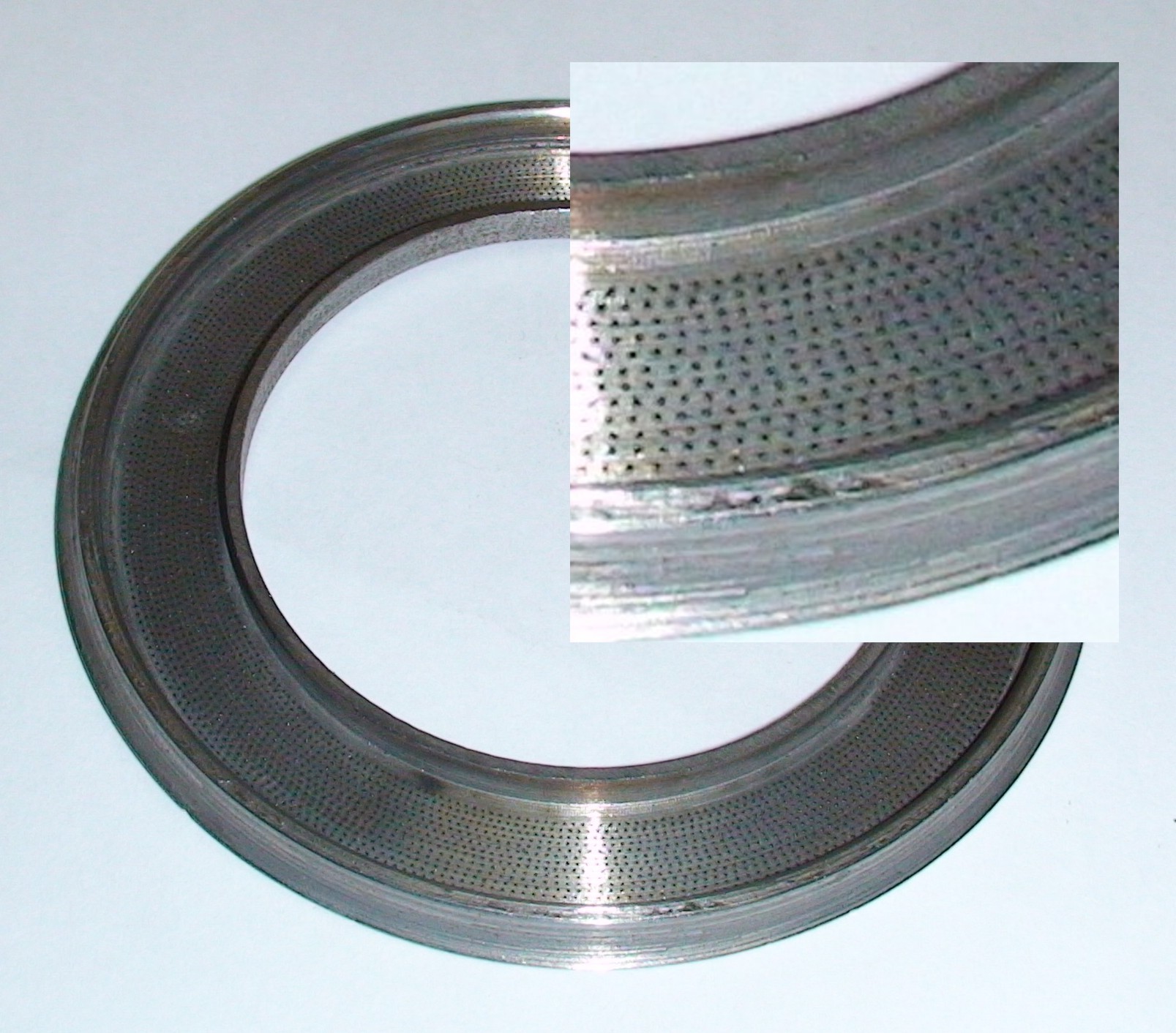

The possibility of random digital modulation of fibre laser radiation allowed to develop

Such filters can withstand high impact pressure differential and can be integrated with case structures.

Filter elements can be manufactured on surfaces of parts that in some cases help to avoid soldering and to simplify the structure. Perforated elements can be manufactured from any metal materials, from steels to copper alloys.

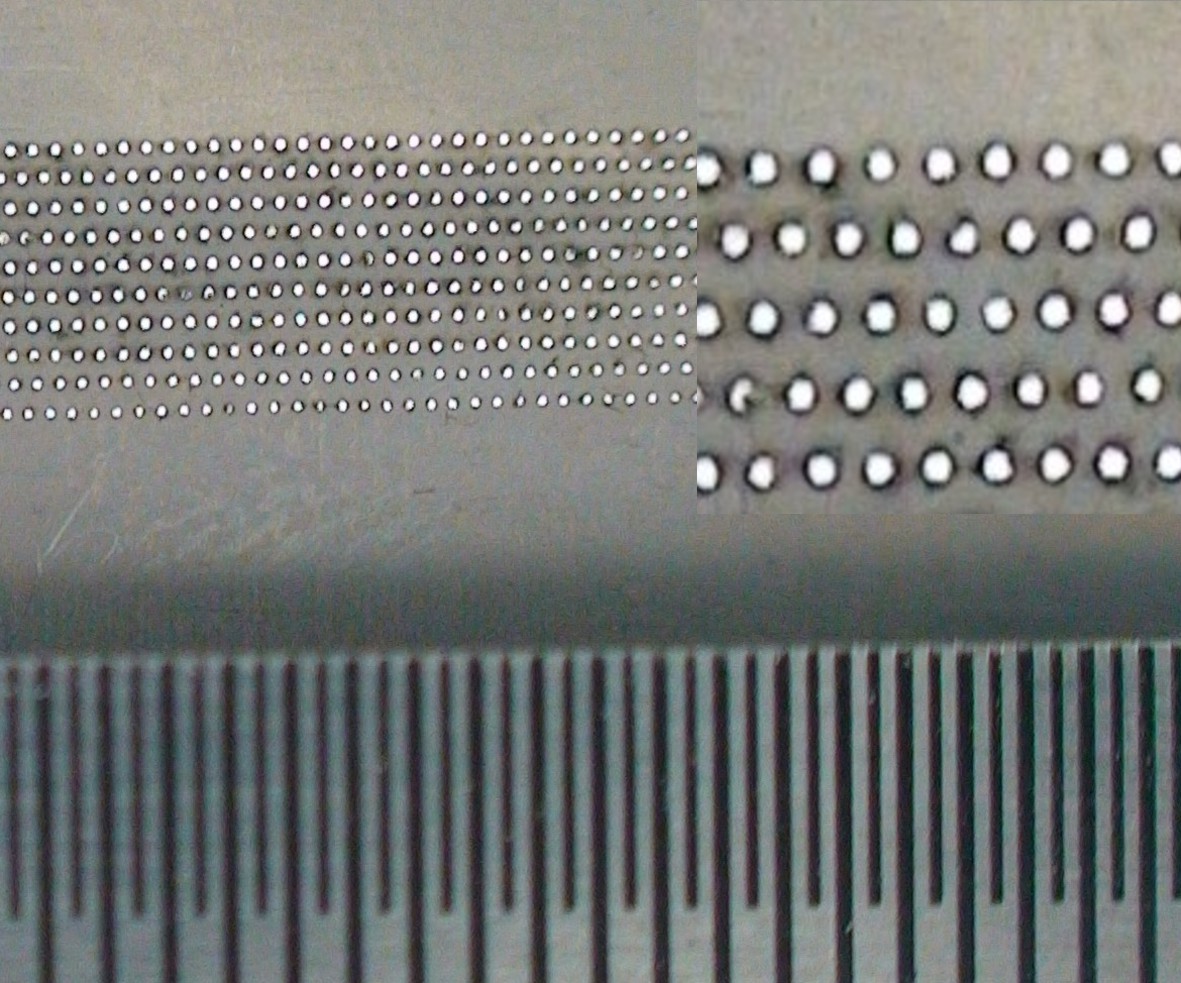

Perforation parameters:

| Hole diameter | 80 to 200 micron |

|---|---|

| Hole ellipticity | 1–5 |

| Punch rate | 200–600 holes/s |

| Material thickness | 0.1 — 1 mm |

| Mesh transparency | 10 — 40% |

| Process efficiency | 0.2 — 0.6 cm²/s |